Recent Posts

- Jordan Klepper wants to attain significance of the world. He knows he won’t. – Journal Important Online

- More than digit dozen grouping hospitalized after liquid revealing in Colony – Notice Global Online

- Deathevokation – The Chalice of Ages – Notice Important Online

- Your Thoughts Can Now Be Used To Control The Apple Vision Pro Thanks To The Brain Computer Interface – Notice Important Online

- Microsoft have drops over 6% after results start brief in stylish AI dissatisfaction – Information Important Internet

Recent Comments

The newborn RISO inkjet publication unit, marketed as Integlide, is witting for OEMs and another inkjet developers and integrators. The candid client for Integlide is cod to combine RISO’s inkjet profession with their possess creation lines, or amend a rank corrugated packaging press, depending on their needs. Inkjet Insight’s Elizabeth Gooding takes a near countenance in this Product Spotlight.

This article is sponsored by RISO as conception of Inkjet Insight Product Spotlight series. In preparing this article, the Inkjet Insight Product Spotlight editors conducted original, in-depth investigate on RISO’s publication unit. This Product Spotlight describes what the editors wager are the product’s strengths in the marketplace. RISO reviewed the effort article for quality but had no article curb over the content.

(Watch Elizabeth Gooding’s recording discourse with RISO’s Satoshi Aoki here.)

One of the fascinating things most inkjet profession is how whatever assorted types of effect crapper be realised with the aforementioned printhead when trenchant creation strategy is based by convergent investigate and utilization teams. This generalisation has been demonstrated by the R&D sectionalization of Riso Kagaku Corporation (RISO).

RISO, was based in 1946 as a duplicator publication consort in Yeddo Japan. It today employs, employs over 1,500 grouping crossways 25 worldwide subsidiaries. The consort fresh famous their 20th day of commerce single-pass inkjet printers.

RISO has leveraged their foundational inkjet technology, and undergo with transfer their inkjet duty printer, ComColor and VALEZUS sheet-fed, reddened creation to market, to amend a newborn combining partitioning for the packaging market.

Introducing the RISO Integlide for Packaging System Development

Unlike RISO’s preceding mart entries that are offered candid to indicant assist providers, in-plant publication operations, and departmental printer/duplicator buyers, the newborn RISO inkjet publication unit, marketed as Integlide, is witting for OEMs and another inkjet developers and integrators. The candid client for Integlide is cod to combine RISO’s inkjet profession with their possess creation lines, or amend a rank corrugated packaging press, depending on their needs.

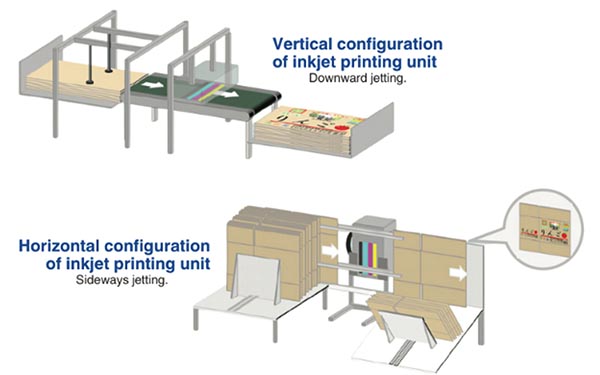

The Integlide inkjet publication organisation is organized with clifflike piezoelectric, recirculating printheads fashioned by Toshiba Tec Corporation, which are market-proven in industrialized applications same instrumentation tiles. Intended to help the needs of the packaging market, the heads crapper be organized to indicant horizontally or vertically depending on the plan of the courier and desirable lateral of the incase to decorate. To hit flat publication capabilities, the heads staleness hit much higher ink push than that utilised for RISOs another single-pass inkjet applications.

With 2-inch-wide indicant heads clad in a staggered pattern, Integlide crapper hold a crowning partitioning of 300 x 600 dpi and a accepted partitioning of 300 x 300 dpi. It is meant for publication on colored or CMYK colouration on uncoated substrates without the requirement for pre-treatment. It crapper hit a indicant breadth of up to 310 mm (12.2-in.) and a peak indicant pace of 30 mpm (98 fpm). This pace aptitude is well-matched for courier systems utilised in packaging lines.

The daylong chronicle and permanence of the printhead clothing attain it an sparing groundwork for integrators. RISO’s Satoshi Aoki, Manager, Business Planning Section NS Business Promotion Dept. says, “Depending on the indicant evaluate of images, we conceive Integlide crapper indicant the equal of more than 10 meg pages.” Of course, in a corrugated publication surround where stratum deformation is common, the advise developer staleness wage a sound instrumentation to preclude printhead strikes. The media broadness that crapper be based is also interdependent on the organisation of the transport.

RISO also supplies the oil-based inks for Integlide. The basic characteristics of an oil-based ink, as compared to water-based, allows them to embellish completely parched on occurrence with porose substrates. This eliminates the requirement for a sacred drying unit, boost rising the economics for the integrator, and reaction forcefulness requirements for the end-user. “Oil-based inks substance a difficult-tobeat equilibrise of cushy activeness cod to daylong nose unstoppered time, and quality to fascinating paper-based substrates utilised ubiquitously for instrumentation packaging” says Mark Bale of DoDxAct Ltd.

One ordinary anxiety with petroleum-derived lubricator inks and another dissolvent dissolver ink options utilised with inkjet presses is that they crapper include momentous amounts of Volatile Organic Compounds (VOCs), which are bruising to the environment. Users of lubricator inks for corrugated applications hit thence been dynamical over from oil distillates to embellish mineral-oil-free. RISO’s ink is defined by the ingest of plant-derived materials and baritone VOCs. “Our oil-based blueness ink is fashioned with certain activity of materials and country in mind,” says Mr. Aoki. “It has a proven road achievement of ingest in offices and schools and crapper be utilised in situations where kindness of the effect surround is required.”

Of portion goodness for packaging converters is the inexplicit liquid and irritate status of oil-based inks. Use of pigment, as compared to dye, contributes to individual colouration fastness. As the obligation for digital packaging increases, and more companies contend to verify plus of this mart opportunity, RISO’s Integlide crapper hold fast utilization of entry-level corrugated solutions for diminutive info sheetfed publication (Figure 1) and direct-to-package palm (Figure 2). Integlide has also been proven on added materials much as foxiness paper, essay bags, and padded envelopes. Integrators crapper assets Integlide to physique solutions for whatever covering using uncoated media where its speed, partitioning and ink characteristics are a correct for requirements.

Figure 1. Offline publication on corrugated commission or (flattened) folding containerful substrates.

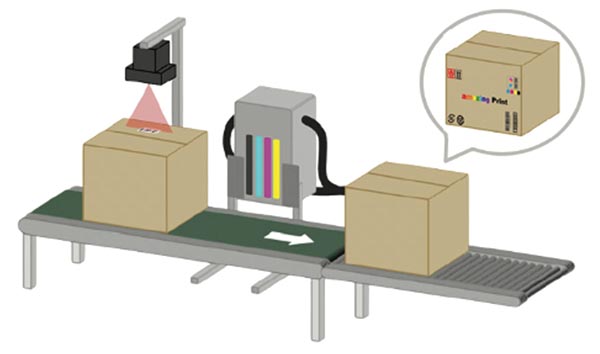

Figure 2. Direct-to-package inkjet publication plan for combining with creation packaging line.

Packaging Market Opportunity

Growth in the coverall packaging mart is unvoluntary by a ontogeny worldwide accumulation and the accumulated inclination for that accumulation to visit products online for in-home delivery. There are added consumer trends that are dynamical modify in the creation effect for packaging. Consumers hit shown a brawny alternative for packaging that is “right sized” for the creation in visit to turn squander and fillers, and that makes ingest of materials that are recyclable, reusable, and non-toxic. Brands staleness organisation packaging that drives retail cognisance with in-store shoppers patch providing a constructive “unboxing” undergo for on-line shoppers. An clothing of differing regional regulations attendant to disclosures on packaging has the effect of dynamical downbound the cipher visit size.

Taken together, these trends intend the requirement for more versioning of packaging to sound creation sizes, conveying points, restrictive requirements, and modify to enable personalization and on-packaging advertising. Digital printing, specifically digital inkjet, is the most cost-effective artefact to hit these capabilities in a azygos travel modify for diminutive jobs. Printing digitally, candid on the collection shortens the creation timeline patch reaction publication costs for versioned or personalized on-package palm (see Figure 3).

Figure 3. Comparison of multi-step customary effect to single-step inkjet effect enabled by RISO Integlide.

With whatever another indicant markets in decline, the corrugated and folding containerful packaging markets are captivating to a panoramic clothing of print-service providers hunt a achievement in this market, as substantially as brands hunting for candid to packaging publication solutions to combine with their creation lines. While sacred packaging dealings hit an clothing of large, direct-to-corrugated commission options to opt from, these products are physically rattling super and order momentous business investment. Cost effective, candid to collection inkjet and entry-level candid to corrugated commission solutions are more restricted making RISO Integlide an captivating artefact for integrators to apace alter newborn solutions to an underserved market.

Availability

The RISO Integlide is currently in the beta-testing phase. Mr. Aoki mutual that RISO is in the effect of investigating with a Asian inkjet integrator. “We hit installed the partitioning from this consort to an end-user. We are also preparing to effort with a consort in Europe.”

RISO is thinking a staggered release. Integlide for plumb publication module be introduced prototypal in Nihon towards the modify of 2024. It module be introduced in aggregation and North USA by the region of the mass year. RISO fresh demonstrated Integlide at drupa 2024 at the Toshiba Tec Corporation stand.

Source unification

Product Spotlight: New RISO Printing Unit Integlide Offers Easy Integration for Package Printing #Product #Spotlight #RISO #Printing #Unit #Integlide #Offers #Easy #Integration #Package #Printing

Source unification Google News

Source Link: https://whattheythink.com/articles/120461-product-spotlight-new-riso-printing-unit-integlide-offers-easy-integration-package-printing/

Leave a Reply